December 2004

Article by Mike Whaley

The wings are progressing. During the hurricane period when there was a very limited amount of work that could be done, we did what we could… John made some durable female molds of the wingtips. We will be offering lightweight and durable fiberglass wingtips (all wingtips will be identical and interchangeable.)

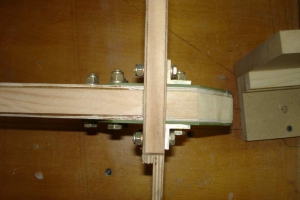

Other areas that we’ve worked on are improving the mechanical aspects of fabricating the parts. For example, we can often combine two or more smaller individual parts into an equivalent single part that can be easily cut out on the router. We have also been able to refine certain part’s shapes to allow for a little more clearance so that another part can be put into place more easily. All the drawings are done in CAD, which we then use to cut most of the parts out on our CNC machining equipment. Therefore, improvements can be made very rapidly and if the nature of the revision warrants it, we can generate a revised part quickly to use on the prototype.

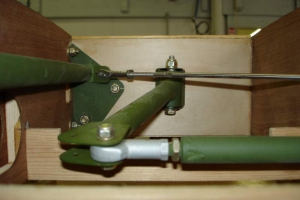

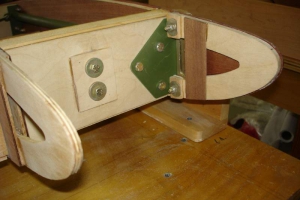

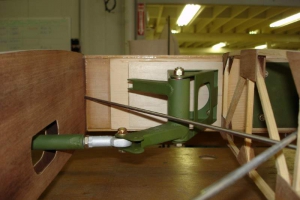

As you view these photos (taken in late 2004) please bear in mind that this is just a snapshot of a work in progress. The wing structure will be refined further before the plane actually flies, and parts of what you see here will be, or have already been, changed to improve the aircraft or building process in some way.

- Lower left wing, December 2004

- Lower left wing, December 2004

- Lower left wing, December 2004

- Lower left wing, December 2004

- Lower left wing, December 2004

- Lower left wing, December 2004

- Lower left wing, December 2004

- Lower left wing, December 2004

- Lower left wing, December 2004

- Lower left wing, December 2004

- Lower left wing, December 2004

- Lower left wing, December 2004

- Lower left wing, December 2004

- Lower left wing, December 2004

- Lower right wing, December 2004

- Lower right wing, December 2004

- Lower right wing, December 2004

- Lower right wing, December 2004

- Upper left wing, December 2004

- Upper left wing, December 2004

- Upper right wing, December 2004

- Wingtip molds, August 2004

- Wingtip molds, August 2004

- Wingtip molds, August 2004

- Wingtip molds, August 2004

- Wingtip molds, August 2004