Project Gallery

Skybolt/Firebolt Projects

Here are some of the projects that our customers have been working on. Do you have a plane flying, being restored, or under construction? We’d love to hear about it! Before sending us digital pictures, please read the file submission guidelines first. Then let us know!

|

||||||||||||

Andreas Kranz’s German Skybolt

- Andreas’ plane is beautiful, to say the least!

- This looks like a very idyllic setting, doesn’t it!

- This shot shows the Skybolt’s graceful lines well.

- Distinctive nose art. Look closely at how neatly Andreas made the cutouts in the sheetmetal where the cabane struts come through. This is typical of the attention he’s put into the details of this project!

- The upper tank has a tried and true sight glass fuel indicator. When the fuel level in the wing tank drops to near empty, a float in the tank also drops with it, and an indicator comes into view in the glass tube.

- Nice hand-painted nose art. Andreas used Ceconite and Randolph coatings.

- The rear view.

- Close-up of the rear of the plane.

- This is where biplanes were meant to be… a beautiful grass field.

- The Skybolt has an elegant outline.

- This view shows the bungee gear well. The constant-speed prop and governor are custom-made by MT for aerobatic use.

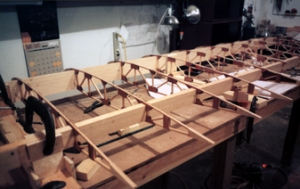

- The Skybolt during construction.

- The pilot’s cockpit is well appointed. Andreas opted to install a clear panel at the bottom of the cockpit.

- The cockpit during construction. Note the great attention paid to detail everywhere you look! The seats are covered in leather.

- The passenger (front) seat only has the basic instruments… airspeed, altitude, and tachometer… and throttle, prop, and mixture controls. You can easily see the landing gear’s bungee installation and the main fuel tank here as well. In the upper left, you can see the pop-up air vent which is accessed by reaching under the dash.

- The Skybolt during construction. The registration hasn’t been added yet.

- It would be pretty hard to miss this engine! It’s a Lycoming O-540-B2B5 that has been reworked into a 300hp AEIO-540.

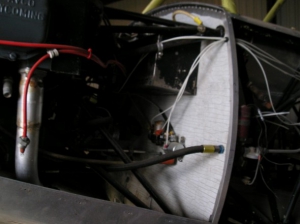

- Detail work on the engine. Nice!

- The engine installation is neatly done. Andreas’ plane reflects a high standard for quality both inside and out.

- The right-side cowl area.

- The front of the airplane before the propeller was installed. You can see the oil cooler inside the cowl, to the right side of the photo.

Andreas Kranz, a really nice guy who also happens to be Steen’s representative for Germany and Europe, sent along these great photos of his newly-completed and very beautiful Skybolt. Andreas began his project in 1992 and spent around 3800 to 4000 spare-time hours to complete it, with help from his good friend Werner Enk. All the components were purchased from Steen Aero Lab. (“The quality is very good and they work great. I build my Skybolt exact to the information and plans from Steen Aero Lab.”, he says.) The engine is a Lycoming O-540-B2B5, built to a 280hp AEIO-540 (300hp with the Ram Air system.) It has a Christen oil system, Air Wolf oil filter, and a B+C alternator and starter. The engine drives a hydraulic constant-speed MT propeller which is specially made for the Skybolt and planes like the Pitts. Low pitch is 9 degrees, high pitch is 30 degrees. The prop governor is also a special item from MT, which works 1.5 times faster than a normal governor. Andreas installed a Steen smoke system as well.

The Skybolt’s empty weight is 1370 lb (623 kg) and the gross weight is about 1900-2000 lb (940kg) with 41.2 gallons of 100LL between the main and wing tanks. The plane is covered with Ceconite using Randolph chemicals and color coats. The cockpits are trimmed with leather and Andeas points out that the aluminum is the same as used in Germany’s Tornado fighter jet, and he elected to install Steen’s bubble canopy for comfort and visibility.

If you look at the photos closely, you can see many outstanding details – such as the rubber coaming around the holes in the upper fuselage sheet metal where the cabanes exit. All in all, this is truly a first-class project all the way. If you get a chance to see this plane up close, you’re in for a real treat!

- Brad works on his Skybolt.

- Here’s an innovative idea – an internal gust lock system which is virtually impossible to forget about before takeoff.

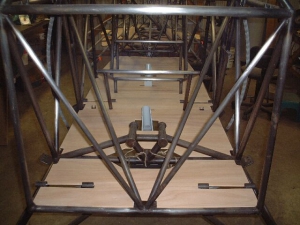

- Fuselage side in the jig at the tack-welded stage.

- Brad built lightweight seats.

- Stainless tailspring polished to chrome!

- Brad built two beautiful throttle quadrants as well… it took some elbow grease, but aren’t they pretty?

- Brad opted to install full floorboards. No chance of feet through the fabric.

- The battery tray and unique vent system.

Brad Roberson is not only a nice guy but he has a good website to chronicle the building of his Skybolt. He has a lot of photos and interesting tips.

Seth Fuller’s Modified Skybolt

- Seth Fuller hard at work (we like his choice of posters…)

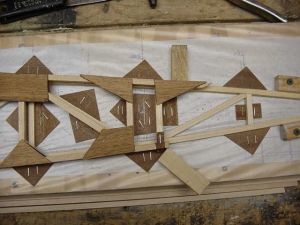

- Rib construction.

- This rib is awaiting the installation of top gussets.

- Fellow Skybolt builder Brad Roberson provided the weights to help hold things down.

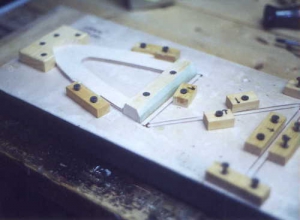

- A rib nose in the jig.

- An aileron rib comes together.

- The ailerons are taking shape.

- The hinge-well area of a friese style aileron.

Seth Fuller in McKinney, TX is building a variation of the Skybolt which is powered by an M14P radial and which has some elements of the Culp’s Special. Seth is currently working on the wings and is documenting his progress on his website.

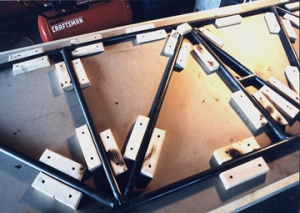

- A fuselage side being assembled.

- The lower rudder and tailpost area.

- Landing gear fitting.

- The rudder being put together in the jig.

- A nearly-finished wing rib.

- Here we can see a wing coming together on the wing table.

- Another view of the wing.

- Wing spar attachment fitting.

Bret Wills is the moderator of the Biplane Hangar and has a Skybolt project well underway.

- Tom Ferraro’s Skybolt.

- This is a sharp-looking airplane.

- Tom’s airplane is IO-360 powered.

- The rear cockpit is a beauty.

Tom Ferraro has an IO-360 powered Skybolt that’s about 20 years old. Seth Fuller has photos and info about this plane on his website.

Pete and Mary Zumwalt’s Skybolt

- Pete with a couple of future pilots. Nearly all kids love to be near a real live airplane!

- They sure chose an eye-catching color scheme… wow!

- Very sporty, yet reminiscent of the Golden Age of Aviation.

- Just waiting to take to the sky…

- Hamming it up for the camera!

- Is it done yet? When can we fly it?

Pete and Mary Zumwalt of Deming, New Mexico took two years to finish their brightly-colored Skybolt N254PM. It has a Lycoming O-540 B2-C5 engine with an Ed Sterba prop. The empty weight came in at 1243 lbs, and the plane has nav lights and a Val com radio. Pete and Mary wanted an open cockpit biplane, so they went for the old WACO look including large, all-original metal wheel pants from a Piper J-3 Cub. The Zumwalts built nearly every part of the plane except for the nose bowl and rear windscreen, and stayed very close to the plans. They did make a mistake in the tail incidence, but once that was straightened out the flights got much better! Pete says “I built a Skybolt because I am a big guy, 270lbs. and 6ft tall.” They covered the plane using the Airtech process and Dupont paint. They haven’t had enough time on it to get performance figures just yet. As you can see by the photos, they are sharing aviation with others and having a great time… they’re proud of their new plane, and justifiably so. Great job, guys!

Mike Robinson’s Skybolt Project

- The top wing is being worked on in Mike’s basement.

- This isn’t the first homebuilt airplane to live in the family room! Mike made sure that there were plenty of potential inspection holes.

- The lower wings have been covered up through the silver UV coats.

- The fuselage on the gear… look at that big 98-inch prop!

- Details of the IO-540 engine with custom ceramic-coated exhaust.

- The rear cockpit instrument panel.

- Mike also restored this attractive 1946 Aeronca Champ.

- Mike’s personal aerodrome… it looks wonderful, doesn’t it!

Mike Robinson of Hartselle, Alabama is working towards the completion of his Skybolt project. He has been working on the Skybolt off and on for quite a few years now, as well as a 1946 Aeronca Champ restoration and conversion to an O-200. Mike is currently spraying the lower wings, using the Poly-Fiber process. His plane has an IO-540 with a polished 90-inch(!) fixed-pitch prop. The engine has a custom ceramic-coated 3-inch exhaust system, inverted smoke system, and inverted fuel and oil systems. The cockpit features basic instruments with moving-map GPS, nav/strobe/landing lights, and a rear canopy/front hole cover with removable front windscreen. The fuselage is stretched 6 inches at the rear seat, and the entire fuselage is covered with screwed-on metal panels all the way back to the tailpost – Mike says that this is great for doing annual inspections! Other features include a wing tank, cockpit-adjustable trim/servo tabs for both the rudder and elevators, a Scott 3200 tailwheel, 7×6.00 oversize tires for the grass airstrip, Pitts-style internal flying wires, and many more options.

Mike also tells us: “In case you’re wondering, the number of inspection hole rings installed on the lower wings reflect my experience in maintaining the Champ here in north Alabama for the past 15 years. You can’t have too many potential inspection holes, especially here in the wet southeast where the mosquitoes are only out-numbered by the number of dirt-daubers!”

Truman Geouge’s Skybolt Project

- Future pilot!

We were recently sent photos of Skybolt builder Truman Geouge (pronounced “Gooj”) and his project. Truman, of Miami, OK, is 83 years old and has had quite the colorful life in aviation… he served in the Navy in WWII, managed the Miami (Oklahoma) airport for about 10 years, and had a crop spraying service for a while. He recently rebuilt a 1946 Swift that he brought home from Montana in pieces, and is now to the point of painting his Skybolt project. Looks great!