June 2003

Article by Mike Whaley

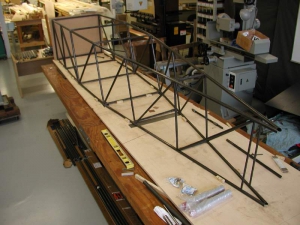

The prototype fuselage was built during the month of June. Curtis returned late in the month to continue the refinement of the design. Things are progressing well… the fuselage is recognizable and on track for an Oshkosh debut.

- The fuselage box is taking shape. The completed side panels are jigged level and plumb. The longerons are heated and bent inward at two stations to join at the tailpost.

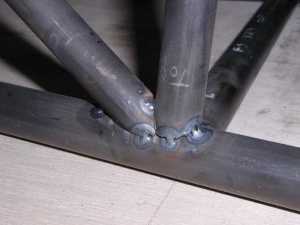

- Many clusters are tack-welded until the basic structure is complete, then they’re finish-welded in schedule order.

- Here is the cross-truss for the new oleo gear, oriented inline with the load.

- Curtis isn’t one to just sit back and watch… here he is laying out a full size template for a construction jig. His pragmatic approach to layout and construction has been optimized over the development of many prototype aircraft.

- Mark Eckenrod tacking-up the fuselage while Curtis works the design. It is an honor to work so closely in the prototype development, and to learn a from his lifetime of experience.

- Rule Number 1 in airframe construction: Do not weld yourself inside the fuselage!